Introduction

Starke 2127 and Starke 2121 are newly developed parking lifts of pit installation, offering 2 parking spaces above each other, one in pit and another on ground. Their new structure allows 2300mm entrance width within total system width of 2550mm only. Both are independent parking, no cars need to drive out before using the other platform. Operation can be achieved by wall-mounted key switch panel.

Starke 2127 and 2121 are Mutrade pit two post parking lifts, by platforms moving upwards from the pit or downwards to the pit, every vehicle can be parked or retrieved conveniently without moving any car else. Starke 2127/2121 is a kind of independent parking equipment, suitable for both commercial and residential parking purposes.

2 cars in a single unit (Starke 2127 and Starke 2121) and 4 cars in a double unit (Starke 2227 and Starke 2221) are both available

Parking space loads: 2100 kg and 2700 kg

Maximum 1700mm high vehicle can be parked in 1900mm deep pit, and 2300mm usable width is

provided in only 2550mm overall width for a single unit, to make full use of the limited space. More

available dimensions are optional for different project requirements.

The structure should be placed in a pit with certain dimensions and reinforced by fixing posts to walls.

Specifications

| Model | Starke 2127 | Starke 2121 |

| Vehicles per unit | 2 | 2 |

| Lifting capacity | 2700kg | 2100kg |

| Available car length | 5000mm | 5000mm |

| Available car width | 2050mm | 2050mm |

| Available car height | 1700mm | 1550mm |

| Power pack | 5.5Kw hydraulic pump | 5.5Kw hydraulic pump |

| Available voltage of power supply | 200V-480V, 3 Phase, 50/60Hz | 200V-480V, 3 Phase, 50/60Hz |

| Operation mode | Key switch | Key switch |

| Operation voltage | 24V | 24V |

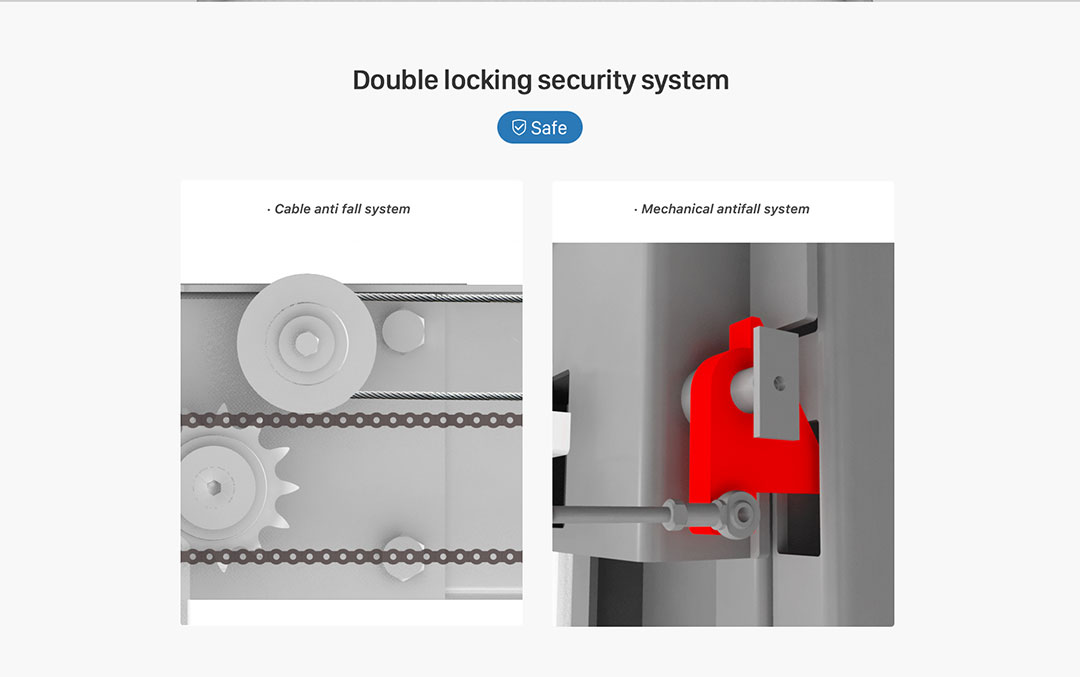

| Safety lock | Dynamic anti-falling lock | Dynamic anti-falling lock |

| Lock release | Electric auto release | Electric auto release |

| Rising / descending time | <55s | <30s |

| Finishing | Powdering coating | Powder coating |

Starke 2127

A new comprehensive introduction of Starke-Park series

TUV compliant

TUV compliant, which is the most authoritative certification in the world

Certification standard 2013/42/EC and EN14010

A new type of hydraulic system of German structure

Germany’s top product structure design of the hydraulic system, the hydraulic system is

stable and reliable, maintenance free troubles, service life than the old products doubled.

New design control system

The operation is simpler, the use is safer, and the failure rate is reduced by 50%.

Galvanized pallet

More beautiful and durable than observed, lifetime made more than doubled

Further intensification of the main structure of the equipment

The thickness of the steel plate and weld increased 10% compared with the first generation products

Gentle metallic touch, excellent surface finishing

After applying AkzoNobel powder, color saturation, weather resistance and

its adhesion are significantly enhanced

Combination with ST2227

Laser cutting + Robotic welding

Accurate laser cutting improves the accuracy of the parts, and

automated robotic welding makes the weld joints more firm and beautiful

Welcome to use Mutrade support services

our team of experts will be on hand to offer help and advice